Torq Drive

Simplified replacement of carbide inserts.

Project description

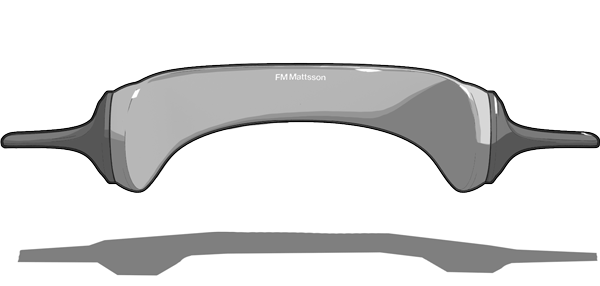

TORQ DRIVE is the result of 4week course in parametric modeling and product analysis at Umeå Institute of design 2016. Our task was to dissect a screwdriver, analyze the construction and design a new enclosure with a specific brand in mind.

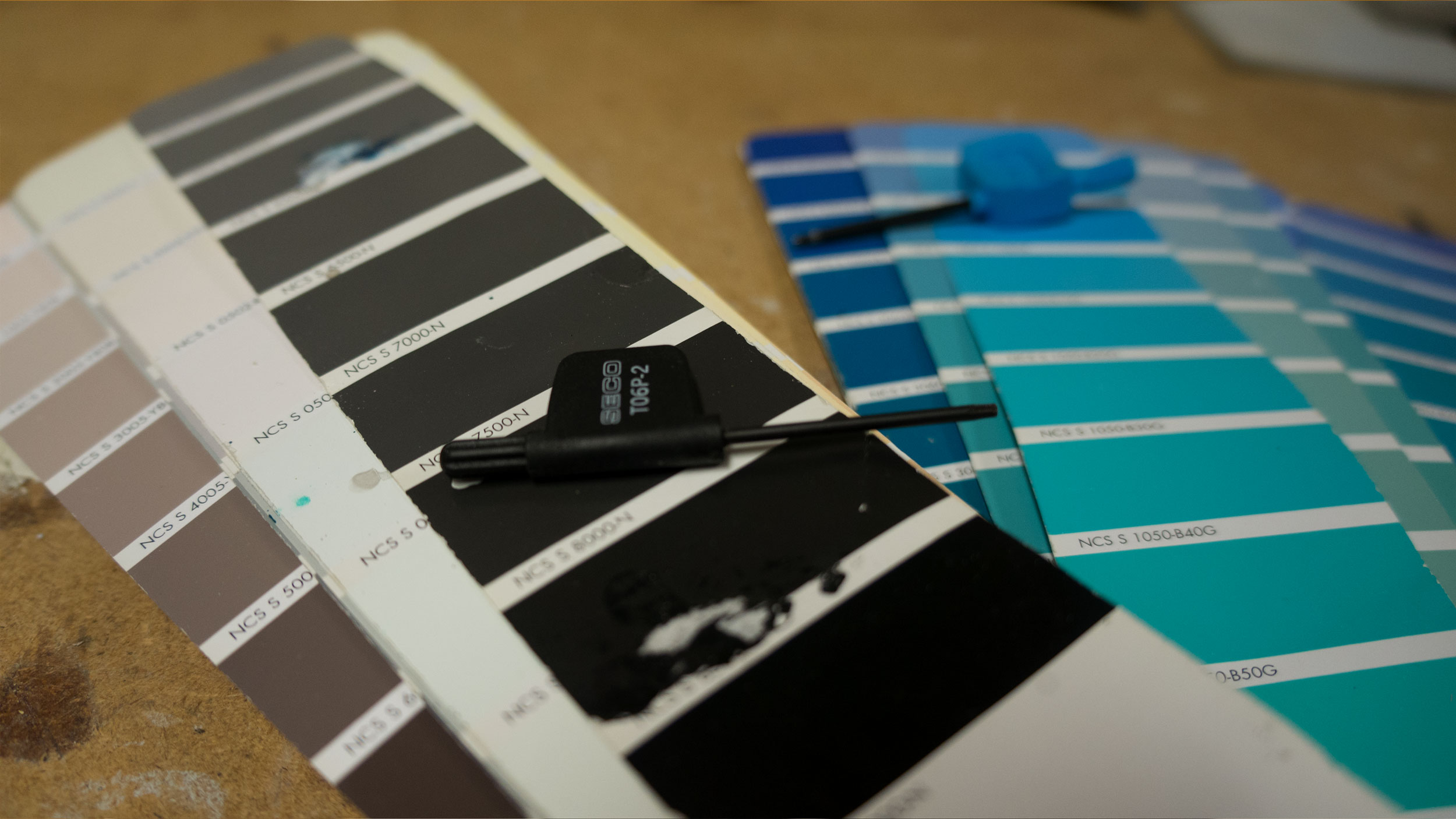

SECO

SECO is one of the biggest manufacturers of carbide inserts in the world. The company was founded 1932 in Fagersta, Sweden. Today they are owned by Sandviken AB.

While working as a CNC-operator I wished there was a power tool with the very specific task of fastening and unfastening carbide inserts, it is tedious work and it is hard to know how hard you need to tighten the screws.

Project Goal

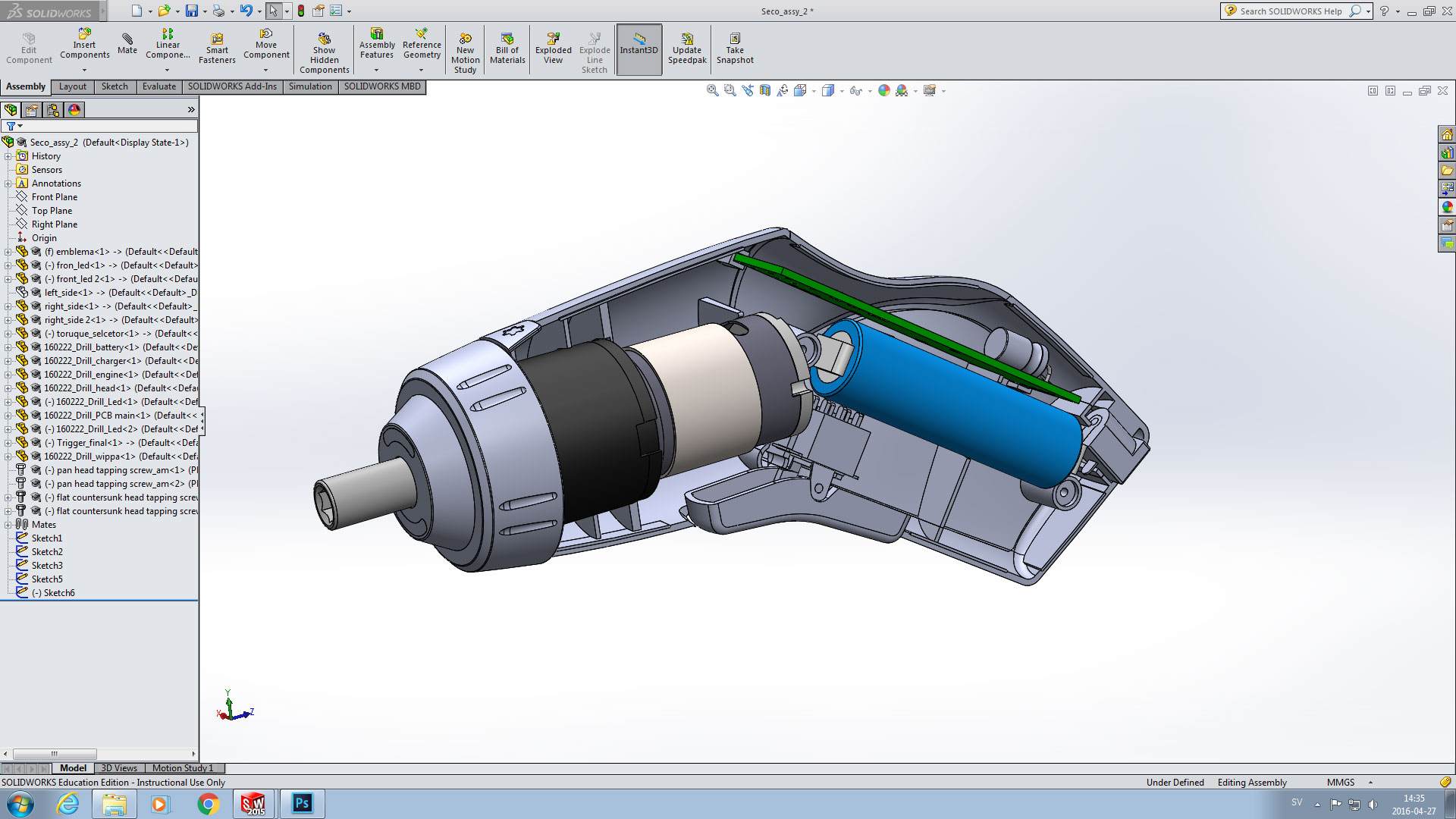

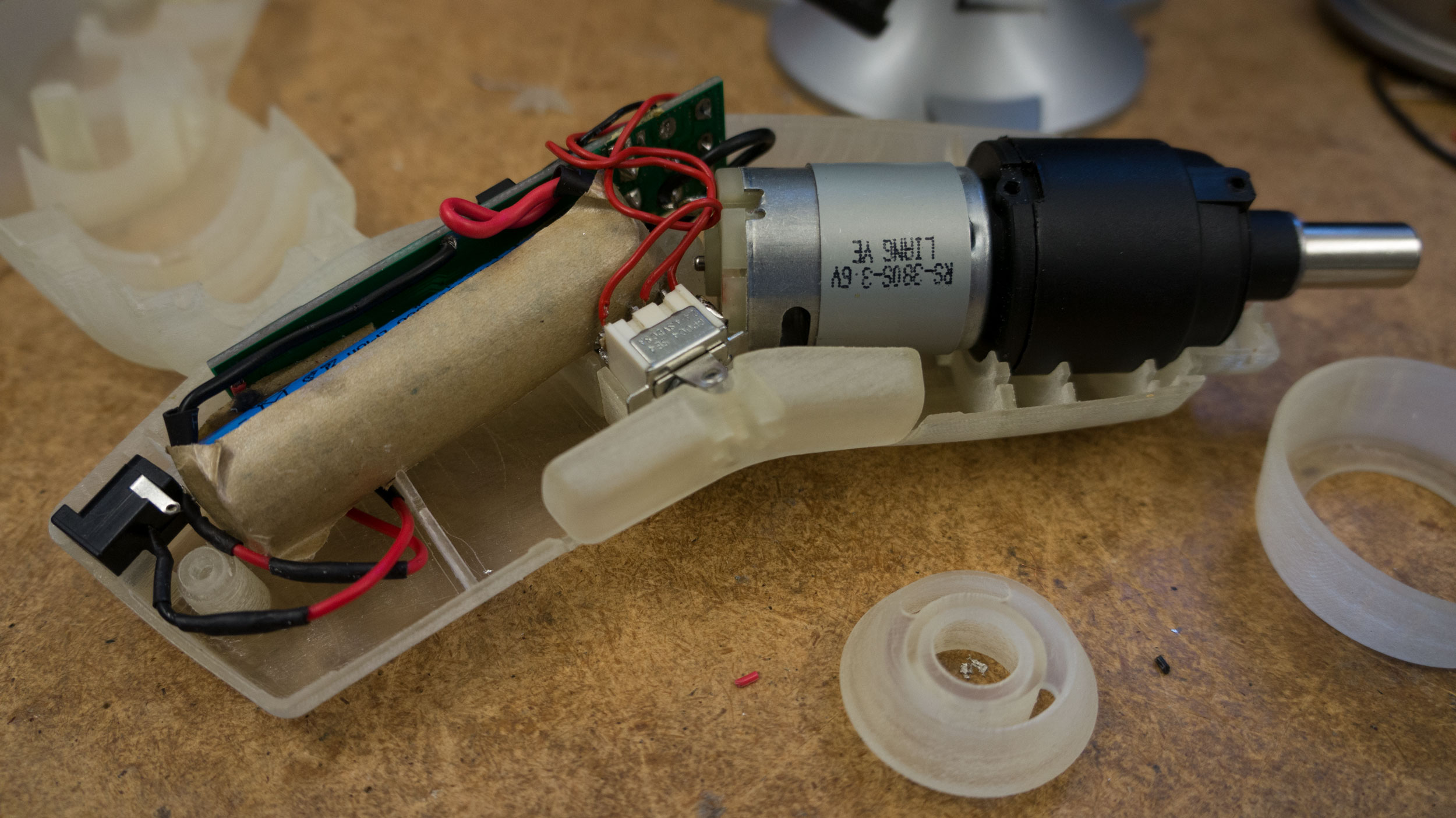

Take the mechanical components from an existing screwdriver and design a new enclosure for them.

Time tracking

We were asked to track our time, with the goal of having a key sketch within 17 hours.

Process

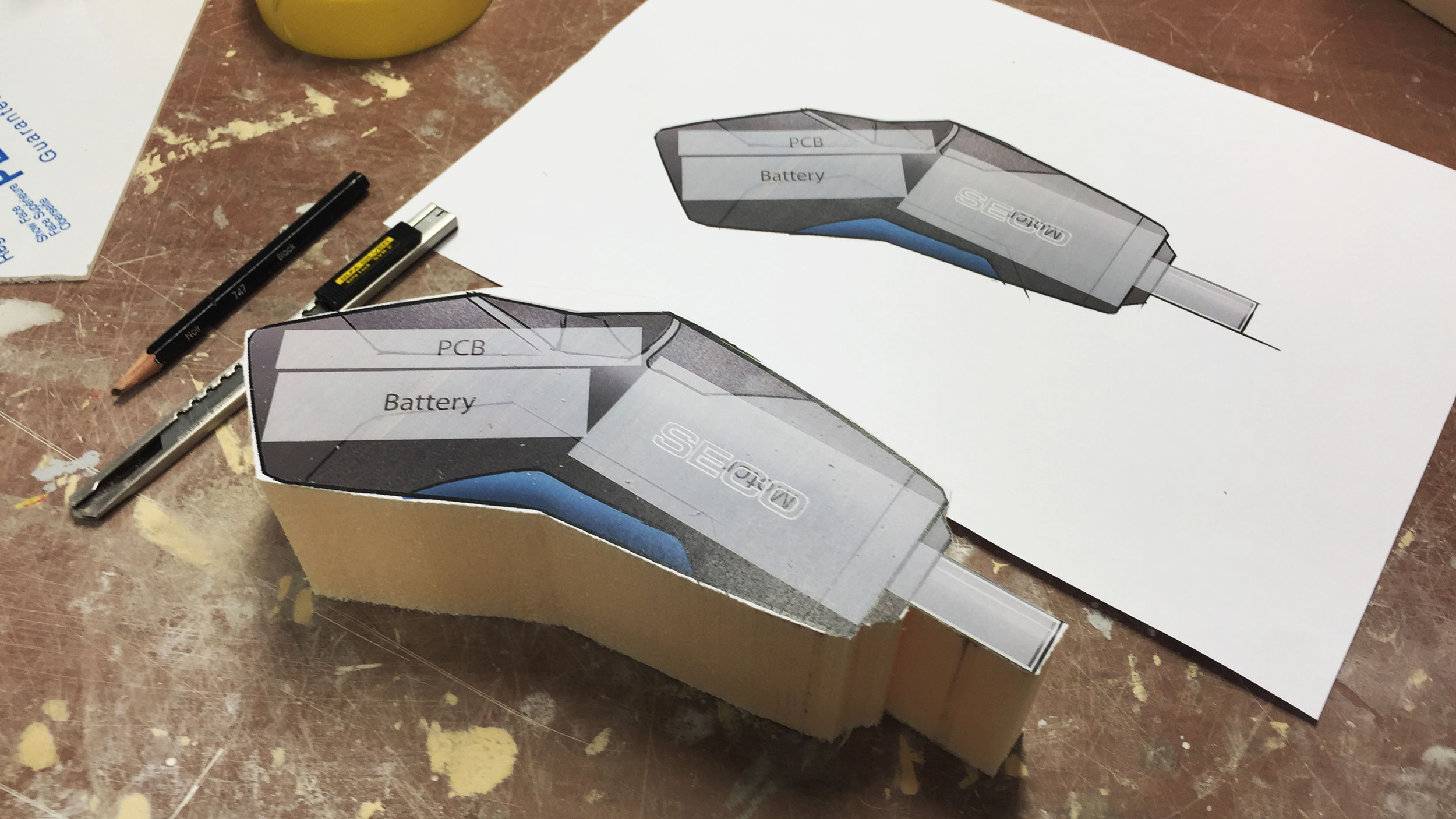

Working both in foam and Photoshop in the design phase allowed me to validate the digital sketches in terms of volume for the components and ergonomics. After 17hours I had a key sketch and a key foam model. The foam model was of great help when modeling the enclosure in Solidworks.

Model making

In the final phase of the project, we 3D printed our designs and assembled the new screwdrivers, using the mechanical components from the old ones.

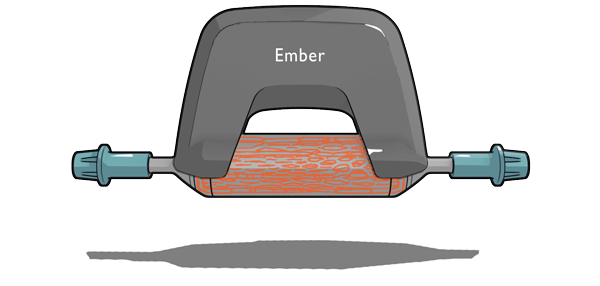

Torqe driver

TORQE DRIVE is a small hand-held screwdriver with five fixed torque options. It is important to tighten the carbide inserts on the milling tool with the correct torque, to keep tolerances and avoid damaging the screw which could result in downtime for the milling machine.